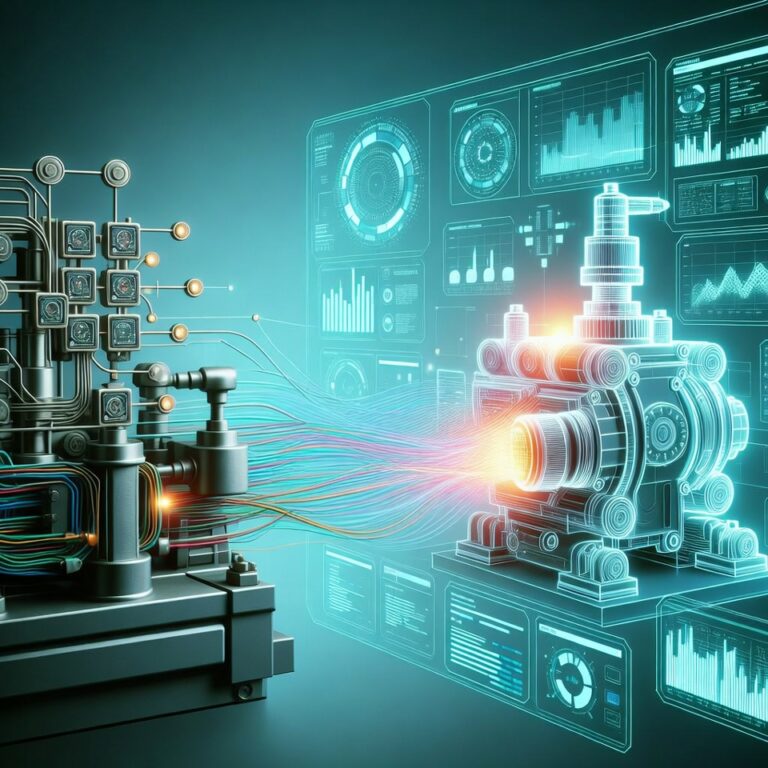

Digital twin technology is transforming the industrial world. Industrial companies use this innovation to improve efficiency in areas like production and energy management. With digital replicas of physical systems, they monitor processes using real-time data, analyze performance, and minimize errors. In this article, we explain how digital twins help companies achieve operational excellence.

What is Digital Twin Technology?

A digital twin is a virtual model of a physical asset. It stays up to date with real-time data. Information from sensors keeps the model current. For example, performance data from machines goes directly to the digital twin. Managers then use this data to manage systems more effectively.

Reducing Errors in Production

Companies that use digital twins detect machine issues early. So operations continue without disruptions. They simulate scenarios and fix problems before production starts. As a result, quality increases and productivity improves.

Improving Maintenance Processes

Digital twins help companies predict equipment failures. For instance, they regularly monitor temperature and vibration data. When the values exceed set limits, the system sends alerts to managers. This reduces downtime and improves efficiency.

Increasing Energy Efficiency

Companies track energy use in real time. When they see losses, they act quickly. Because of this, costs drop and environmental impact lessens.

Making Data-Driven Decisions

Managers base their decisions on real-time data. Because the data comes from the field, it is reliable. So decisions become faster and more accurate.

The Future of Manufacturing

AI and machine learning let digital twins check their own performance. They also offer suggestions to improve results. So production becomes smarter and more automated. In the future, digital twins will also improve quality control, supply chains, and logistics.

Conclusion

Digital twin technology is now essential for industrial companies. Real-time data and fast responses give them an edge. So they build a more efficient and sustainable production system.