Globally, in major metropolitan areas such as New York, London, and Singapore, as well as in critical industrial operations like energy transmission networks, the cost of disruptions can reach billions of USD. At TwinUp, we manage the transition from traditional calendar based maintenance strategies to Predictive Maintenance (PdM) powered by Machine Learning (ML) and Digital Twin technologies. This transformation positions failure prediction at the core of global Operational Risk Management and Sustainability strategies.

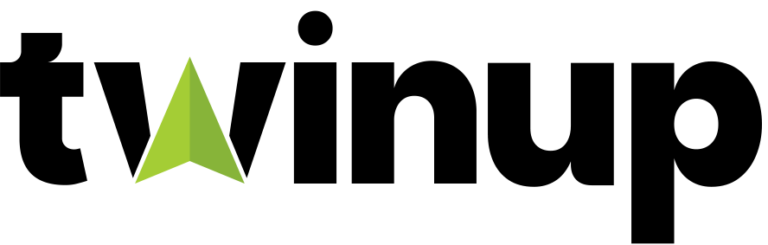

I. Technical Architecture: Three-Layered PdM Integration (Data – AI – Twin)

The Predictive Maintenance solution is built on the synchronization of three technology layers to generate actionable intelligence about the performance and lifespan of critical infrastructure assets.

1. Data Pipeline and Preprocessing (Real-Time Data Stream)

- Data Sources: High frequency time series data (vibration, temperature, pressure) are collected from Industrial IoT (IIoT) devices, SCADA, and Enterprise Asset Management (EAM) systems.

- Data Quality Management: Raw data is filtered and corrected using algorithms such as Kalman Filtering to remove noise and handle missing or erroneous measurements.

- Normalization: Sensor outputs are standardized using statistical methods (Z-Score and Min-Max normalization) and enhanced with Geo-Tagging for global infrastructure assets.

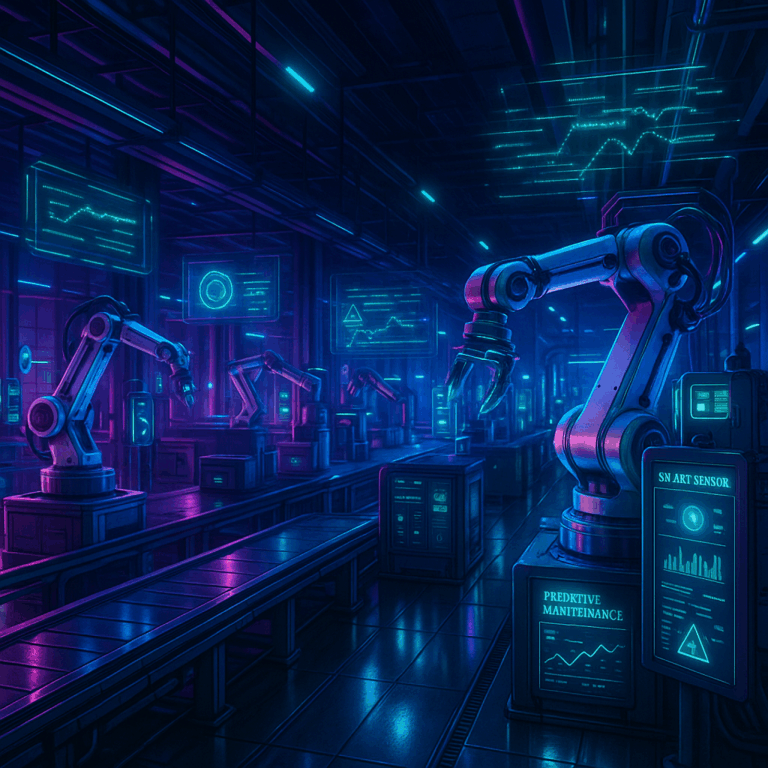

2. Artificial Intelligence Modeling (Anomaly and Failure Prediction)

a. Anomaly Detectio

- Objective: Identify deviations from normal operational behavior before a physical failure begins.

- Technique: Unsupervised models such as Autoencoders or One Class SVM learn normal operational patterns, flagging any significant deviation as a potential anomaly, generating early warning signals.

b. Remaining Useful Life (RUL) Prediction

- Objective: Predict the exact time until an asset reaches a critical failure threshold.

- Technique: LSTM networks or Weibull distribution-based statistical models learn the degradation curve of an asset and estimate the future time window for optimal maintenance intervention.

3. Digital Twin and Scenario Optimization (Decision Support System)

- Definition: Predicted RUL information is integrated into the TwinUp Digital Twin platform, which mirrors the physical and operational behavior of assets in a virtual environment.

- Scenario Analysis: Discrete Event Simulation (DES) or Monte Carlo methods simulate the operational and financial impact of various maintenance actions (immediate intervention, postponement, part replacement).

- Decision Optimization: Multi Criteria Decision Making (MCDM) algorithms automatically select the scenario that minimizes Life Cycle Cost (LCC) and operational risk.

II. Global Impact and Operational Benefits

1. Financial and Operational Efficiency

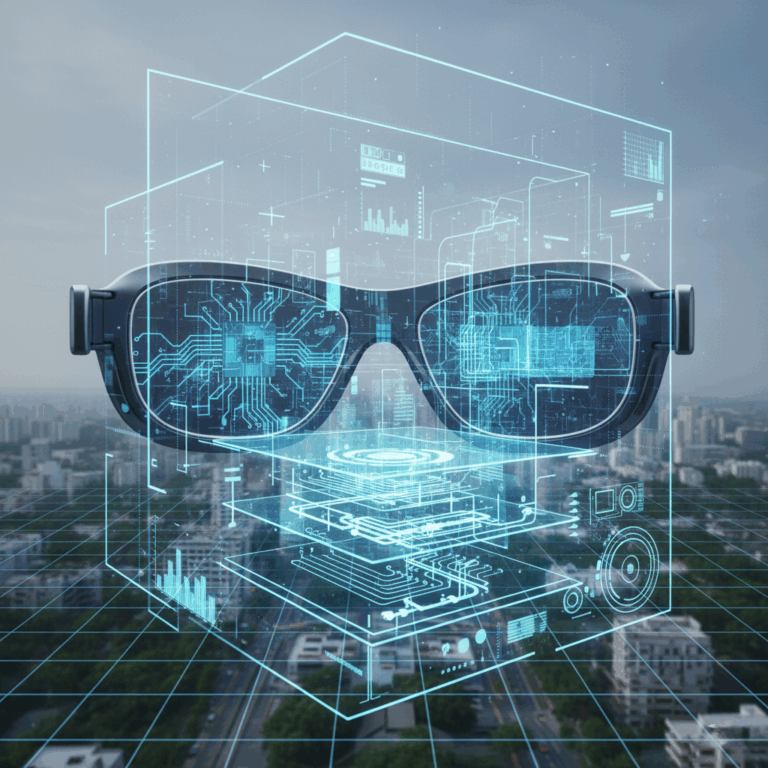

- Minimizing Unplanned Downtime: PdM reduces unplanned stoppages by 30–50%, improving key operational metrics such as MTTR and MTBF.

- Optimized Maintenance Budget: Compared to traditional calendar based maintenance, PdM achieves 5–20% cost savings, as interventions are performed just in time.

2. Sustainability and ESG Alignment

- Energy Efficiency Preservation: AI detects efficiency drops early (e.g., a pump consuming excess energy due to wear) and allows corrective action before failure, supporting global ESG objectives.

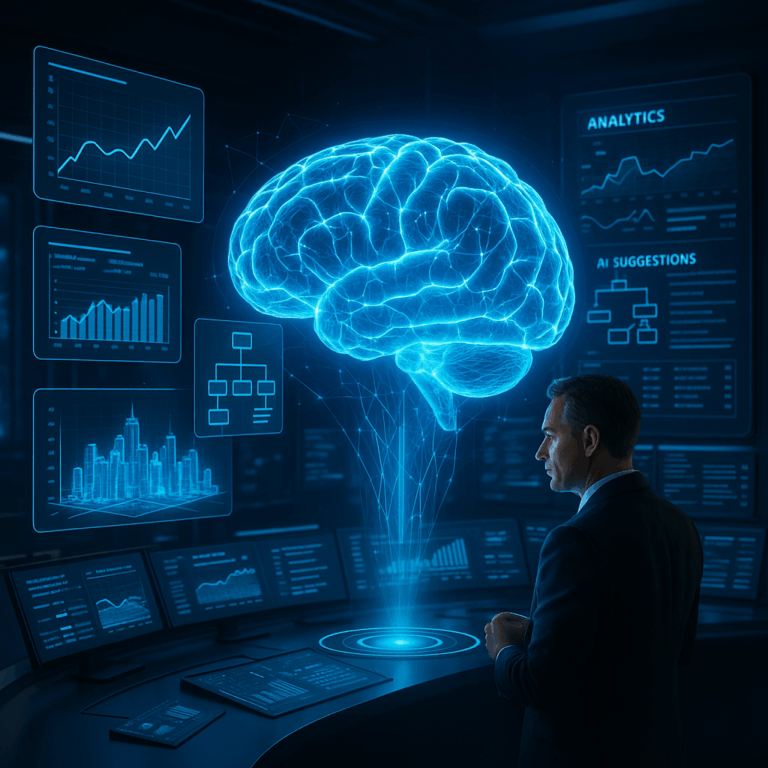

3. Autonomous Decision Support

- AI Driven Action Recommendations: AI generates optimal maintenance schedules, resource allocation, and expected operational benefits. Human operators use these recommendations to make strategic decisions quickly and accurately.

Conclusion: TwinUp and the Future of Asset Management

By combining Digital Twin technology with Artificial Intelligence, TwinUp enables global infrastructure managers to not only protect their assets but also operate them in a cost effective, environmentally sustainable, and resilient manner. Predictive Maintenance is a cornerstone of operational intelligence and the future of modern asset management.