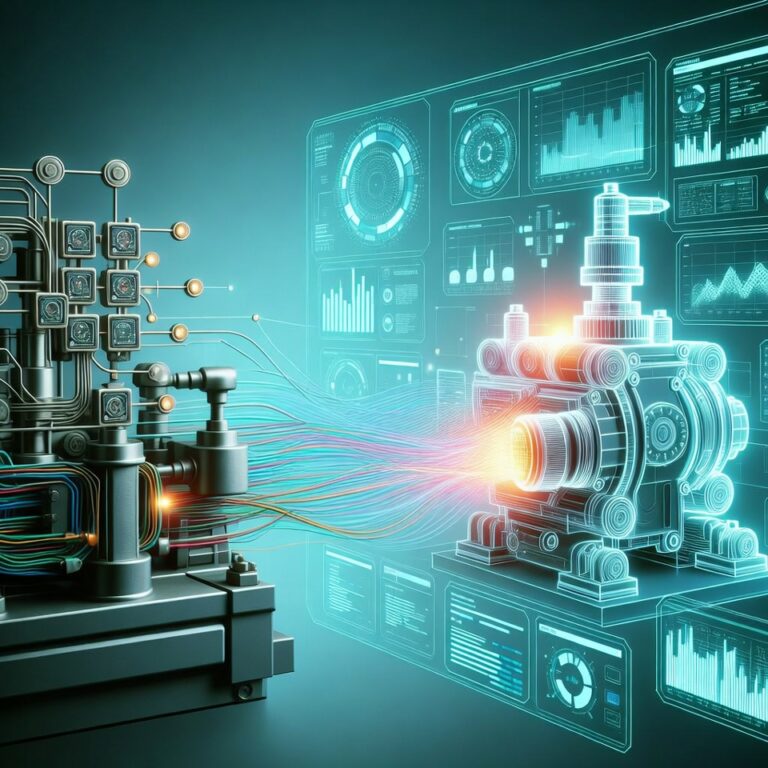

Digital twin technology is one of the most innovative components of the industrial revolutions. This technology offers real-time simulations of physical assets in a digital environment. It enables direct application across a wide range, from design and production to maintenance and performance monitoring. As companies adopt digital twin technology, they improve operational efficiency and gain a competitive edge.

In this article, we’ll clearly examine the innovative solutions provided by digital twins and the advantages they offer businesses.

What Is a Digital Twin?

A digital twin is a dynamic digital reflection of a physical asset. The system continuously updates itself using data collected from sensors, generating real-time insights. For instance, the digital twin of a jet engine reflects all functions and parameters of the engine in real time while it operates. Therefore, companies can run tests without damaging equipment and detect problems early.

Innovative Solutions

1. Real Time Monitoring

Digital twins allow real-time monitoring of systems. Managers can transparently observe every stage of the operation. Moreover, they identify potential issues quickly and intervene promptly.

2. Simulation and Forecasting

Companies use digital twins to test various scenarios in a virtual environment. This reduces risks and helps determine the most suitable strategies. Additionally, AI-powered analytics make system behaviors easier to predict.

3. Predictive Maintenance

Companies can forecast equipment failures and plan maintenance processes more effectively. This prevents production interruptions and saves valuable time.

4. Advanced Data Analytics

Digital twins analyze big data and generate meaningful insights. As a result, decision-making becomes more data-driven. Furthermore, machine learning continuously improves these systems over time.

5. Process Optimization

This technology helps maximize efficiency in production and operational processes. For example, material usage and energy consumption can significantly improve.

Advantages of Digital Twins

1. Cost Savings

By detecting unexpected malfunctions in advance, companies manage their resources efficiently. Consequently, costs decrease, and profitability rises.

2. Operational Efficiency

Quick and accurate decisions streamline operations. This boosts the productivity of both employees and machines.

3. Sustainability

Digital twins optimize energy and resource use, which helps reduce environmental impact. Thus, it becomes easier to achieve sustainability goals.

4. Risk Reduction

Managers conduct tests in virtual environments to foresee and avoid real-world errors. This minimizes risks in product development and operations.

The Future of Digital Twin Technology

As digital twins integrate more deeply with artificial intelligence and the Internet of Things, they will form the foundation of more autonomous systems. Especially in sectors like smart cities, agriculture, logistics, and healthcare, this technology will become increasingly widespread. Therefore, companies should embrace digital twin solutions to build agile and sustainable systems.

Conclusion

Digital twin technology lies at the heart of industrial transformation. With its innovative solutions, it not only boosts efficiency but also provides strategic advantages. Hence, adopting digital twins is essential for companies that aim to stay competitive in the future.