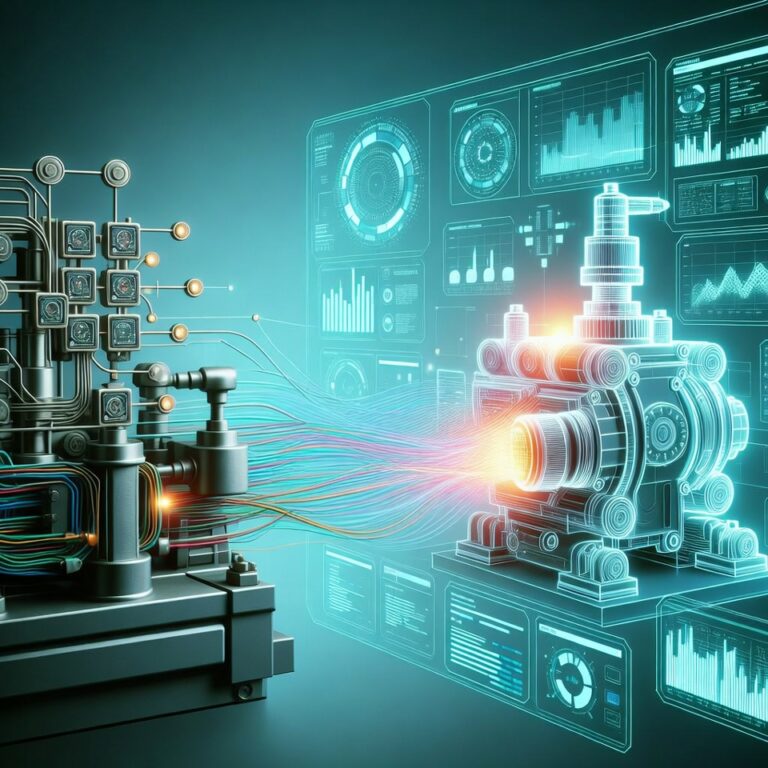

Digital twin technology gives game-changing opportunities to today’s companies. It creates a virtual copy of a physical object or system. This technology helps businesses work more efficiently and make smarter decisions in areas like production, maintenance, logistics, and energy management.

Strategic Management with Real-Time Data

Digital twins collect real-time data through IoT sensors and deliver it to decision-makers. Companies rely on data, not assumptions. For example, they can detect possible machine failures early on a production line. So, this prevents downtime and saves costs.

From Guesswork to Data-Driven Decisions

Depending on gut feeling is not enough anymore. Digital twins analyze historical data and discover trends. Because of this, businesses can anticipate problems and plan better. They use smarter strategies and manage resources more effectively.

Driving Operational Excellence

Digital twins improve planning and day-to-day operations. Smart production systems and energy optimization solutions become more powerful with digital twins. So, businesses increase efficiency and reduce environmental impact.

Learning and Evolving Continuously

Digital twins are not static. They collect data, learn, and update themselves regularly. As a result, they provide better predictions. So, companies can adapt quickly to market changes.

Advantages in Every Industry

Logistics companies use digital twins to plan routes with traffic and weather data. High-energy systems work better during peak hours. Also, factories can find maintenance needs before a breakdown happens.

Shaping the Future of Decision-Making

When integrated with AI, machine learning, and big data analytics, digital twins do more than just report data. They also give smart recommendations. So, they actively support decision-making.

Conclusion

Digital twins give businesses efficiency, flexibility, foresight, and a competitive edge. That’s why they are essential for the smart, sustainable business models of the future.